DEFENSE TRACKS

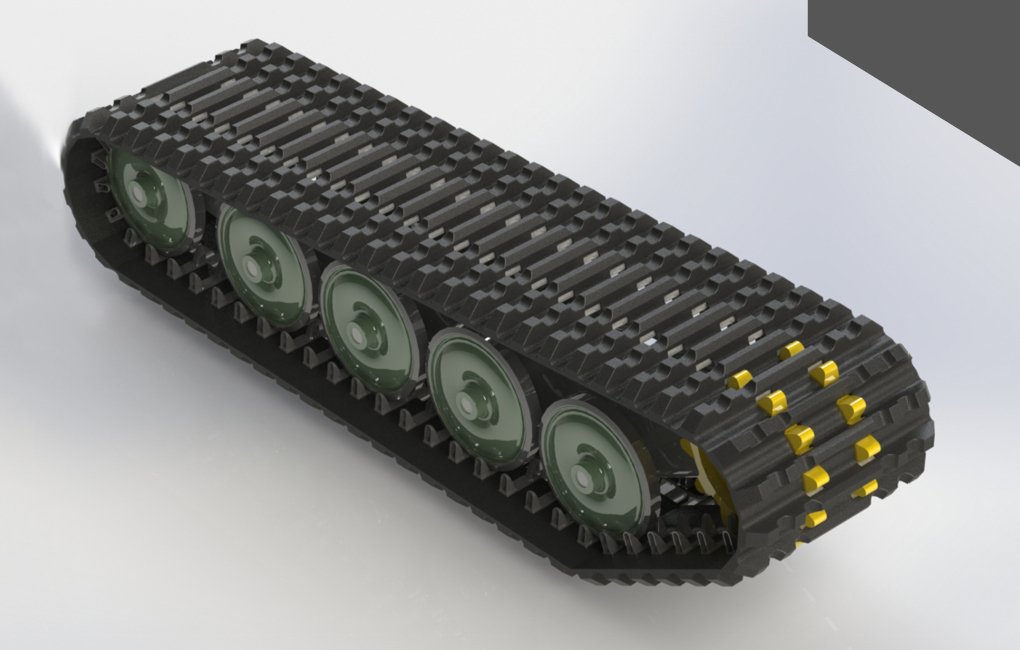

High-Performance Solutions for Military

We develop high-performance rubber tracks for military tanks and other defense vehicles, ensuring mobility and safety on any terrain. Our solutions are designed to meet specific mission requirements, supporting diverse applications from armored vehicles to unmanned ground vehicles (UGVs). By leveraging advanced technologies, we provide integrated and accessible track solutions that deliver the durability, reliability, and performance essential for all defense operations.

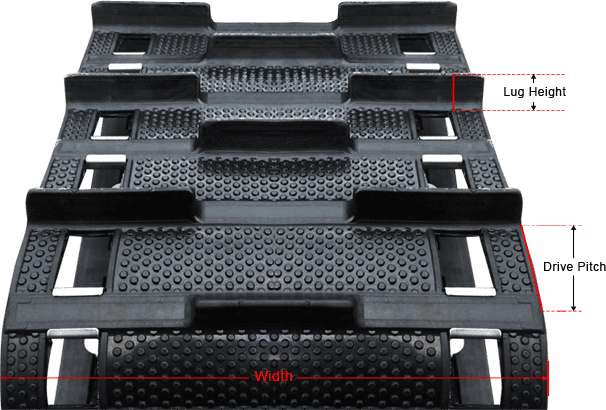

The 5 Key to Track Selection

Rubber Track Size

Track Width

Track Lug Height

Track Drive Pitch

Track Length

Track Links

Hagglund BV206 Rubber Track 620x90.6x64 (Kevlar)

| Width | 620mm | 24.4" |

| Pitch | 90.6mm | 3.6" |

| Length | 5798.4mm | 228.3" |

- Vehicle: Hagglunds BV206 all terrain vehicle

- Application: snow, mud, sand, flood

- Lightweight and fuel saving

Hagglund BV206 Rubber Track 620x90.6x64 (Iron)

| Width | 620mm | 24.4" |

| Pitch | 90.6mm | 3.6" |

| Length | 5798.4mm | 228.3" |

- Vehicle: Hagglunds BV206 all terrain vehicle

- Application: snow, mud, sand, flood

- Tough and durable

Hagglund BV206 Drive Sprocket

| Diameter | 370mm | 14.6" |

- Aluminum inside, nature rubber outside

- Interchangeable with Hagglunds BV206 original drive sprockets

Hagglund BV206 Road Wheel

| Diameter | 346.2mm | 13.6" |

- Aluminum inside, nature rubber outside

- Interchangeable with Hagglunds BV206 original road wheel

Custom Track Production Process

Discover how we tailor rubber tracks to meet your unique needs.

We begin by listening to you. Your unique needs and specifications are our top priority. Whether it's size, logo, pattern, or performance features, our team gathers all the necessary details to ensure your custom rubber track is a perfect fit.

Our expert designers create precise 2D and 3D models tailored to your specifications, including size, logo, and pattern. These detailed technical drawings are reviewed and refined with your input to ensure they meet all your requirements before moving to mold production.

We develop the molds with state-of-the-art technology. The time needed to produce the mould can range from 30 to 60 days, depending on the track size and technical complexities.

Once the mould is completed, we conduct rigorous testing and produce several track samples for your evaluation. This sample production process usually takes 3-5 days.

You test the track samples under real-world conditions and provide feedback. If adjustments are needed, we modify the mold to meet your exact specifications. Typically, our samples pass customer tests on the first try, allowing us to quickly proceed to mass production.

With your approval of the track samples, we begin bulk order production. The production timeline can vary depending on the specific track design and the quantity required.

Before shipment, each track undergoes a thorough final inspection to ensure it meets all specifications and quality standards. Once approved, tracks are carefully packaged to prevent any damage during transit.

We offer flexible shipping options to suit your needs. Whether you prefer to use your own designated shipping forwarder or take advantage of our reliable and cost-effective shipping partners, we ensure timely and safe delivery of your order.

Rubber Tracks

- Heavier and tougher for extended track life

- Full warranties - no pro-rata warranties with us

- One of the largest dedicated rubber track inventories

- Expert engineers to ensure you get the right size

- Super fast delivery

Performance &Reliability

VEJEETRACK designs and manufactures rubber tracks for leading Original Equipment Manufacturers (OEMs) worldwide. Our unique expertise ensures that all VEJEETRACK rubber tracks enhance your machine’s performance and extend component longevity. This is your guarantee of reliable performance and outstanding durability.

20 Years of Expertise

With two decades in the rubber track industry, we bring unmatched experience and insights to every project, ensuring your needs are met with precision and reliability.

Various Sizes To Choose From

What’s more, we offer a wide range of rubber track sizes to suit your specific needs. Whether you need tracks for snowmobiles, ATVs, construction machinery, or agricultural equipment, we have the perfect fit for you.

Made To Fit

Customized on Demand

Whether you’re working in mud, sand, snow, or any other extreme conditions, VEJEETRACK has the solution for you! Tailored to meet any specification—be it length, width, or tread pattern—our tracks are designed to enhance performance and durability in any application. Partner with us to transform your specific requirements into high-quality solutions that drive your projects forward.

National High-Tech Enterprise

As a recognized high-tech enterprise with multiple patents, VEJEETRACK is dedicated to pushing the boundaries of what’s possible in rubber track technology, ensuring you always have access to cutting-edge solutions.

Excellent Customer Service

We’re more than just a supplier; we’re your partner. Our team is committed to providing top-notch pre-sales consultation, after-sales support, and ongoing technical assistance to help you succeed.

Factory-Direct Pricing

Cut out the middleman and enjoy competitive pricing directly from our factory. Experience cost savings without compromising on quality.

Need Another Reason To Choose Us?

Here's 5 More!

Premium rubber formula

Advanced Jointless Tech

Durable Kevlar Fiber

ISO9001-2015 Certified

Precision Molding Techniques

Frequently Asked Questions

Are the tracks compatible with the original Hägglunds BV206

We have manufactured and delivered rubber tracks for Hägglunds BV206 for a number of years, so you can trust our experience and expertise to provide a seamless replacement for the original tracks.

What is the lead time for BV206 rubber track orders?

Lead time varies based on order size, standard orders typically take 4-6 weeks. We will provide an estimated delivery date upon receiving your specifications.

Do you offer samples for BV206 drive wheels?

Yes, we can provide samples for testing. Please contact us, and we will arrange for sample delivery.

How do you ensure the quality of your BV206 rubber tracks?

Our tracks undergo strict quality control processes, including ISO9001 certification standards. Each track is tested for durability, performance, and consistency before shipment.

Can you assist in the development of new rubber track for remote control vehicles?

Yes, our experienced R&D team can collaborate with you to develop high performance rubber tracks and drive sprockets to fit numerous different types of remote control vehicles.