RUBBER TRACK PADS

Reliable Rubber Track Pads for Heavy Equipment

VEJEETRACK offers three types of rubber track pads—Bolt-on, Clip-on, and Chain-on. Available in widths ranging from 300mm to 800mm, our rubber track pads increase traction and protect hard surfaces such as asphalt and concrete, while minimizing turf damage on various worksites. They are also ideal for enhancing traction on hard, abrasive surfaces.

- Excavators

- Mini Dozers

- Compact Track Loaders (CTLs)

- Skid Steers

- Trenchers

- Directional Drills

- Concrete Pavers

- Crawlers

- Other Steel Tracked Vehicles

Sizes – 300 mm to 800 mm

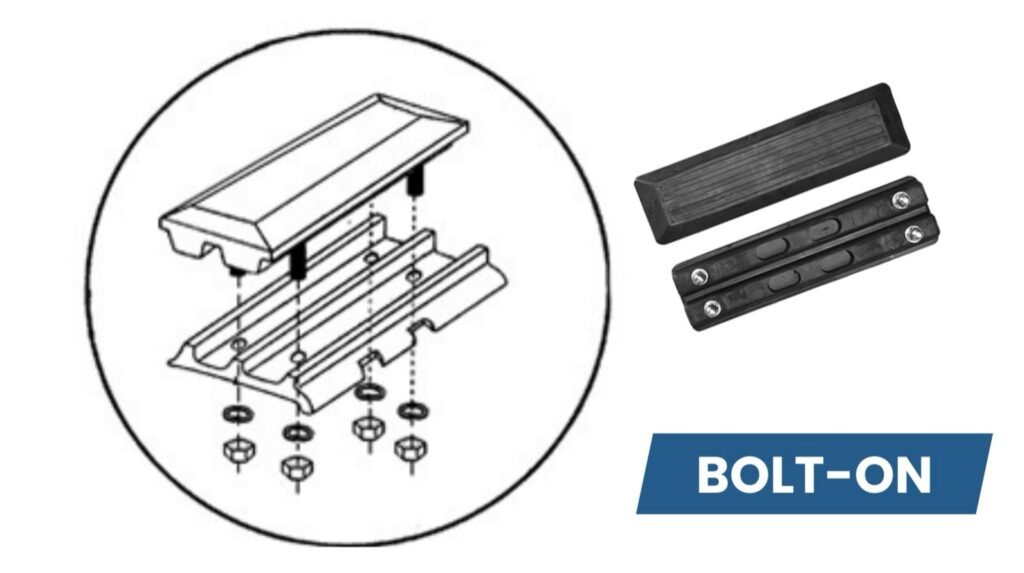

Bolt-On Track Pads: Economical and Durable Solutions

Bolt-On excavator track pads are designed for easy installation on existing grouser shoes with pre-drilled holes. Bonded to pre-formed metal plates, these track pads fit seamlessly between steel grousers, providing an economical and durable option for enhancing traction and surface protection. Perfect for compatible steel tracks, our Bolt-On track pads ensure reliable performance across various applications.

Clip-On Rubber Track Pads: Easy Installation and Extended Service Life

Clip-On rubber track pads are designed for excavators with triple grouser steel tracks, whether or not they have pre-drilled mounting holes. These pads feature special hardened mounts for side installation, making the process simple and efficient. Heavier and containing more rubber and steel than bolt-on pads, Clip-On pads reduce wear and minimize the risk of delamination, often providing a longer service life.

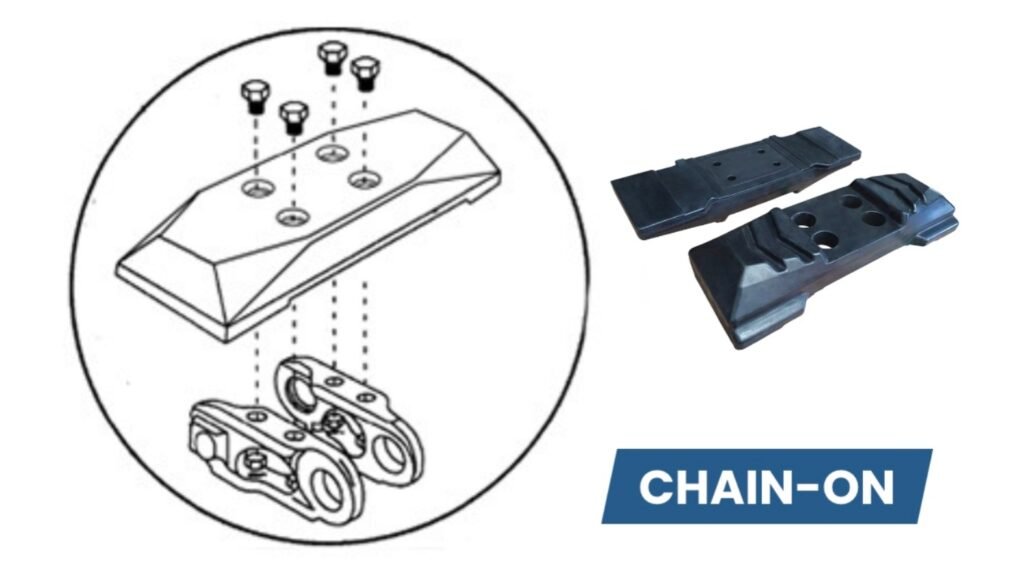

Chain-On Rubber Track Pads: Durable and Protective Solutions

Chain-On rubber track pads, also known as “Road Liner” pads. Bolting directly to the steel chain of the undercarriage, these pads provide complete rubber enclosure of the steel tracks, protecting them from side impacts. Chain-On pads deliver the durability of a steel undercarriage with the enhanced performance of continuous rubber tracks.

Custom Track Production Process

Discover how we tailor rubber tracks to meet your unique needs.

We begin by listening to you. Your unique needs and specifications are our top priority. Whether it's size, logo, pattern, or performance features, our team gathers all the necessary details to ensure your custom rubber track is a perfect fit.

Our expert designers create precise 2D and 3D models tailored to your specifications, including size, logo, and pattern. These detailed technical drawings are reviewed and refined with your input to ensure they meet all your requirements before moving to mold production.

We develop the molds with state-of-the-art technology. The time needed to produce the mould can range from 30 to 60 days, depending on the track size and technical complexities.

Once the mould is completed, we conduct rigorous testing and produce several track samples for your evaluation. This sample production process usually takes 3-5 days.

You test the track samples under real-world conditions and provide feedback. If adjustments are needed, we modify the mold to meet your exact specifications. Typically, our samples pass customer tests on the first try, allowing us to quickly proceed to mass production.

With your approval of the track samples, we begin bulk order production. The production timeline can vary depending on the specific track design and the quantity required.

Before shipment, each track undergoes a thorough final inspection to ensure it meets all specifications and quality standards. Once approved, tracks are carefully packaged to prevent any damage during transit.

We offer flexible shipping options to suit your needs. Whether you prefer to use your own designated shipping forwarder or take advantage of our reliable and cost-effective shipping partners, we ensure timely and safe delivery of your order.

Rubber Tracks

- Heavier and tougher for extended track life

- Full warranties - no pro-rata warranties with us

- One of the largest dedicated rubber track inventories

- Expert engineers to ensure you get the right size

- Super fast delivery

Performance &Reliability

VEJEETRACK designs and manufactures rubber tracks for leading Original Equipment Manufacturers (OEMs) worldwide. Our unique expertise ensures that all VEJEETRACK rubber tracks enhance your machine’s performance and extend component longevity. This is your guarantee of reliable performance and outstanding durability.

20+ Years Experience

We Know Our Rubber Tracks

With over 20 years of industry experience, VEJEETRACK has the expertise, capability, and capacity to meet a wide variety of rubber track needs. Since our establishment, our goal has been to meet and exceed your expectations for quality, reliability, and on-time delivery.

Comprehensive Product Range

From snowmobiles to construction machinery, our extensive range of rubber tracks and wheels covers a wide variety of industries, ensuring we have the right product for your specific application.

Scalability

Whether you need a small batch for a prototype or a large order for mass production, VEJEETRACK has the capacity to scale our production to meet your needs, without compromising on quality.

Long-Term Partnerships

We value relationships over transactions. Our focus is on building long-term partnerships with our clients, offering consistent support and collaboration to help you grow your business.

Super Fast Delivery

As a manufacturer, VEJEETRACK takes full ownership of the process from start to finish. This ensures your orders arrive promptly, helping you meet your deadlines and keep your projects on track.

Factory-Direct Pricing

No middlemen, no hidden costs—just direct access to high-quality rubber tracks at competitive prices. With over 20 years in the industry, we know how to optimize production for cost-efficiency.

Need Another Reason To Choose Us?

Here's 5 More!

Premium rubber formula

Advanced Jointless Tech

Durable Kevlar Fiber

ISO9001-2015 Certified

Precision Molding Techniques

Frequently Asked Questions

How to Choose the Right Track Rubber Pads?

Choosing the right track rubber pads involves considering several factors to ensure optimal performance and cost-effectiveness. Here are the key elements to consider:

Type of Machine: The type of machine—whether it’s a standard excavator, compact track loader, or specialized asphalt milling machine—dictates the required track pad design. Pads for excavators might differ in size and compound from those used on milling machines due to differences in weight and function.

Terrain and Surfaces: The typical terrain and surfaces the machinery will encounter play a crucial role in selecting track pads. Softer pads are often best for delicate surfaces to prevent damage, while more robust designs might be necessary for rough, abrasive terrains like dirt and gravel. Additionally, consider the level of traction needed for your application.

Costs: Evaluate both upfront costs and long-term implications. While high-quality track pads might come with a higher price tag, they often offer better durability and performance, reducing labor costs and the frequency of replacement. Warranty terms should also be considered to ensure protection against premature wear.

What are the Advantages Offered by Track Pads?

Track pads, particularly rubber track pads, are essential components for heavy construction machines using steel track shoes like excavators and bulldozers. They are designed to optimize performance and safety. Key advantages include:

Protection Against Steel Track Damage: Track pads, especially those made from durable compounds, protect delicate surfaces such as asphalt, concrete roads, curbs, sidewalks, and grassy areas from the potential damage caused by steel tracks. This makes them ideal for urban or residential areas where infrastructure protection is crucial.

Reduced Noise and Vibration: High-quality track pads minimize noise and vibration, which is crucial for maintaining peace in noise-sensitive areas and reducing unnecessary wear on machinery.

Enhanced Traction on Varied Surfaces: Rubber tracks and track pads provide superior traction on unstable or slippery surfaces, which is vital for maintaining efficiency and safety in challenging environments.

Extended Wear Time: By buffering the harsh contact between heavy equipment and the ground, track pads extend the maximum wear time of both the tracks and the terrain. This ensures long-term cost savings and less frequent replacements.

Should I Choose Bolt-On, Chain-On or Clip-On Tracks?

Choosing between bolt-on pads, chain-on pads, and clip-on track pads depends on the specific requirements of your construction machinery and project needs.

Bolt-on rubber pads, which are screwed onto the track plates, offer an extremely durable solution for intensive use. Their design allows for easy assembly and disassembly, making it convenient to adapt the machine quickly to various surfaces. This secure attachment enhances their resistance to tough conditions.

Chain-on rubber pads, mounted directly on the chain, distribute weight and wear evenly along the track. Known for their durability and suitability for intensive use, these pads combine robust performance with straightforward maintenance. They also provide comprehensive protection by enclosing the steel portion of the tracks with rubber, shielding them from side impacts.

Clip-on rubber pads, clamped around the plate, offer a cost-effective and flexible solution. Easier and quicker to assemble and disassemble compared to bolt-on pads, they are ideal for operations requiring frequent changes between different job types. Their ability to be mounted on existing plates enhances their versatility.

How Long Should Rubber Pads Last?

It depends on ground conditions, working application and hours worked. For general use on roads, you could expect 3-4 years but with coarse ballast material such as rail maintenance 1-2 years.

How do I know if I am getting the correct product and if it will fit the machine?

Our customer service team will ensure they check the track size for your machine using our extensive machine cross reference. They will then ensure they confirm the track size matches what it currently on the machine. If for some reason an error is made, you will be able to swap the track out hassle free.

Do Rubber Track Pads Require Special Maintenance?

Rubber track pads require regular maintenance to ensure they remain in good condition. This includes cleaning them regularly to remove dirt and debris, checking for signs of wear and tear, and replacing them when necessary. Consistent maintenance helps extend the lifespan of the pads, ensuring they continue to provide optimal performance and protection for your machinery.